Understanding Production Capacity and Lead Times of Industrial Bathroom Mirror Manufacturers

Understanding Production Capacity and Lead Times of Industrial Bathroom Mirror Manufacturers

For procurement managers and hospitality developers, securing a reliable supply of industrial bathroom mirrors is critical to project timelines. Understanding the intricacies of a manufacturer's production capacity and the variables that dictate lead times allows for better planning and risk mitigation. In the B2B sector, capacity is not merely about stock levels; it involves the synchronization of raw material sourcing, glass processing, electronics integration, and rigorous quality control protocols.

Defining Production Capacity in Mirror Manufacturing

Production capacity in the context of industrial bathroom mirrors refers to the maximum output a factory can sustain over a specific period, typically measured in units per month. This metric is heavily influenced by the level of automation in the facility, such as CNC glass cutting tables, automatic edging machines, and laser engraving systems. A manufacturer with fully automated production lines can handle high-volume orders for hotel chains with consistent precision, whereas semi-automated lines may offer more flexibility for smaller, custom batches but with lower total throughput.

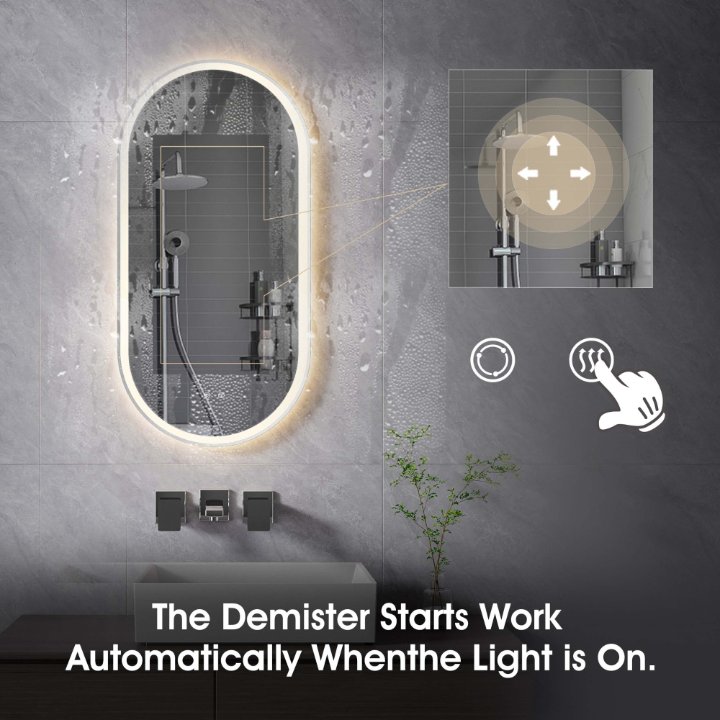

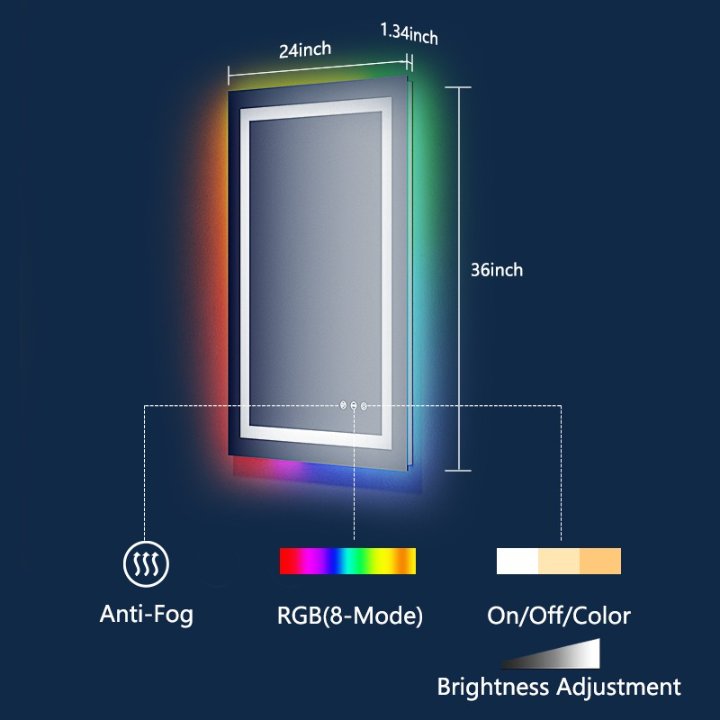

Capacity is also dictated by the assembly workforce's size and skill, particularly for LED mirrors that require manual installation of light strips, drivers, and defoggers. Evaluating a supplier's scalable labor force is essential for understanding how they manage peak season demands without compromising quality.

Key Factors Influencing Manufacturing Lead Times

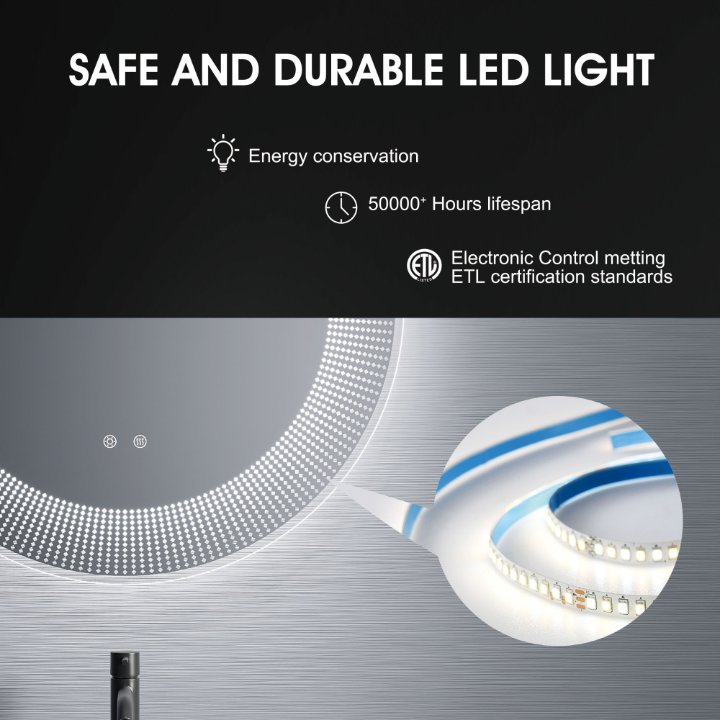

Lead time extends beyond the assembly line. It encompasses the entire lifecycle from order confirmation to shipment readiness. One of the primary drivers of lead time is raw material availability. High-quality copper-free silver mirror glass and specific LED components (such as drivers compliant with UL or CE standards) may have their own procurement cycles. If a manufacturer relies on Just-In-Time (JIT) inventory for critical components, supply chain disruptions can cause significant delays.

Furthermore, quality assurance processes add necessary time to the schedule. Reputable manufacturers conduct aging tests—often running LED mirrors for 24 to 48 hours—to ensure driver stability and thermal management before packaging. Skipping these steps to rush an order often results in higher failure rates post-installation.

The Impact of Customization on Schedules

Standard catalog items generally have the shortest lead times, as tooling and component specifications are pre-established. However, commercial projects often require OEM or ODM solutions, such as specific dimensions, unique sandblasting patterns, or integrated smart features like Bluetooth or dimming sensors. Customization introduces additional phases: engineering design, prototyping, and client approval.

For example, creating a new mold for a custom frame or programming a specific lighting temperature (CCT) requires setup time that reduces immediate production capacity. Procurement teams must factor in an additional 2-4 weeks for the prototyping and approval phase before mass production begins.

Comparison: Standard vs. Custom Order Timelines

The following table outlines typical lead time expectations and capacity impacts for different types of industrial mirror orders.

| Order Type | Typical Lead Time | Capacity Impact | Primary Bottleneck |

|---|---|---|---|

| Standard Stock Models | 7 - 15 Days | Low | Packaging & Logistics |

| Bulk Project Orders (Standard) | 25 - 35 Days | High | Assembly Line Scheduling |

| Custom OEM/ODM (New Design) | 45 - 60 Days | Medium | Prototyping & Tooling |

| Certified Safety Mirrors (UL/ETL) | 30 - 45 Days | Medium | Component Sourcing & QC Testing |

Supply Chain and Logistics Considerations

Production completion does not equal project readiness. Industrial bathroom mirrors are fragile, heavy, and often bulky, requiring specialized packaging solutions such as reinforced honeycomb cartons or wooden crates for palletized shipping. The logistics phase—booking containers, customs clearance, and final delivery—can add 2 to 6 weeks depending on the destination and shipping method (sea freight vs. air freight).

Manufacturers with experience in export logistics will often have established relationships with freight forwarders, helping to streamline this process. However, during global shipping crunches or peak holidays, even the most efficient production lines can be bottlenecked by a lack of available containers.

Strategies for Optimizing Procurement Timelines

To navigate capacity constraints and lead times effectively, early engagement is crucial. Providing manufacturers with rolling forecasts allows them to reserve production slots and procure raw materials in advance. For large-scale hospitality projects, approving a "golden sample" early in the development phase prevents delays during mass production.

Additionally, understanding the manufacturer's Minimum Order Quantity (MOQ) policies can influence lead times. Consolidating orders to meet optimal batch sizes often results in smoother production runs compared to fragmented, smaller orders that require frequent line changeovers.

Frequently Asked Questions

1. How does the Minimum Order Quantity (MOQ) affect production lead times?Higher MOQs typically allow for continuous production runs, which are more efficient and less prone to setup delays. Smaller orders may be scheduled between larger batches, potentially extending the wait time until a production slot opens.

2. Can lead times be expedited for urgent commercial projects?Expediting is sometimes possible but depends on current factory capacity and raw material stock. It may incur additional costs for overtime labor or air freight shipping. It is best to discuss critical deadlines during the initial quotation phase.

3. Do safety certifications like UL or CE impact the production timeline?Yes. Mirrors requiring specific safety certifications must use certified components and undergo strict compliance testing during assembly. If a custom design requires new certification listings, this can add significant time to the pre-production phase.

4. How do Chinese New Year and other holidays affect production capacity?Major holidays, particularly Chinese New Year, can shut down production for 2-4 weeks. The period immediately before and after the holiday is also characterized by high congestion and reduced workforce, significantly extending lead times.

5. What is the difference between production time and total lead time?Production time refers strictly to the manufacturing process (cutting, assembly, testing). Total lead time includes order processing, material procurement, production, packaging, and shipping transit time to the final destination.

Recent Posts

- Understanding Production Capacity and Lead Times of Industrial Bathroom Mirror Manufacturers

Master industrial bathroom mirror procurement. Understand production capacity, lead time factors, and supply chain logistics for large-scale commercial projects

12/29/2025

- Why Global Importers Prefer Specialized Bathroom Mirror Manufacturers Over General Glass Suppliers

Global importers prefer specialized bathroom mirror manufacturers for IP44 safety, LED integration, and copper-free durability. Secure your B2B supply chain.

12/29/2025

- Where to Buy Bathroom Mirrors | Find LED Vanity & Framed Mirrors | DAPAI Mirror

Searching for the perfect bathroom mirror? Whether you're wondering "where to buy a bathroom mirror" or "where is the best place to buy bathroom mirrors", this guide will help you navigate the options and choose the best mirror for your home. From LED bathroom mirrors to framed vanity mirrors, we’ve gathered all the essential tips to make the right choice.

03/11/2025

- How to Hang a Bathroom Mirror Above Your Vanity: Tips for Optimal Placement

Hanging a bathroom mirror above your vanity is more than a functional necessity—it's a design decision that enhances the beauty and usability of your space. Whether you’re installing a brand-new vanity or upgrading your bathroom mirror, knowing how high to hang a bathroom mirror is essential for creating a visually appealing and practical bathroom setup. In this guide, we’ll share step-by-step tips and design considerations to ensure your mirror is perfectly positioned.

03/11/2025

- The Ultimate Guide to Hanging Your Bathroom Mirror: Height, Tools, and Techniques

Installing a bathroom mirror is more than just an aesthetic upgrade—it’s a crucial element in both functionality and design. Whether you're placing a vanity mirror, a wall-mounted LED bathroom mirror, or a large decorative mirror, precision in height, tools, and installation technique is essential. This guide walks you through every step to ensure a secure and visually appealing mirror setup.

03/11/2025

- Step-by-Step Guide: How to Hang a Bathroom Mirror with Precision

Installing a bathroom mirror may seem like a small task, but doing it with precision can elevate your space's entire look and functionality. Whether you're upgrading to a new LED bathroom mirror or replacing an existing one, this guide will walk you through the complete process—perfect for DIY enthusiasts and professionals alike. With DAPAI Mirror's bathroom mirrors designed for easy installation, you’ll have a flawless setup in no time.

03/11/2025

- How High to Hang a Bathroom Mirror: A Comprehensive Guide for Perfect Proportions

Hanging a bathroom mirror at the correct height is essential for both functionality and aesthetics. Whether you’re installing a new mirror or adjusting the height of an existing one, the right placement can transform your bathroom space. In this guide, we’ll cover everything from standard height recommendations to factors that influence mirror placement, ensuring that your mirror complements your vanity and bathroom layout.

03/08/2025

- How to Hang a Bathroom Mirror: Expert Tips for a Perfect Installation

Installing a bathroom mirror might seem daunting at first, but with the right guidance, tools, and a little patience, you can achieve a flawless, professional installation on your own. In this comprehensive guide, we will walk you through each step of the process—from measuring and leveling to securing the mirror on your wall—ensuring that your new mirror not only functions perfectly but also enhances the overall aesthetics of your bathroom.

03/08/2025

- How to Frame a Bathroom Mirror: Budget-Friendly Options

Framing your bathroom mirror doesn’t have to break the bank. In fact, with a little creativity and the right approach, you can transform a plain mirror into a stunning focal point that complements your bathroom’s décor without spending a fortune. Whether you are working with a small vanity mirror or a larger bathroom mirror, there are plenty of budget-friendly methods to create a custom frame.

03/08/2025

- Do It Yourself: Creating Beautiful Bathroom Mirror Frames

In today’s design-driven world, every detail in your home matters – especially in your bathroom. A well-framed mirror not only reflects your image but also elevates the overall aesthetic of your space. Whether you’re looking to add a touch of elegance to a modern bathroom or create a warm, inviting atmosphere in a traditional setting, creating your own bathroom mirror frame is a fantastic way to add personal flair and save money.

03/08/2025

English

English  Spanish

Spanish  Polish

Polish  German

German  Arabic

Arabic  French

French  Russian

Russian