DAPAI Mirror - Factory Introduction

DAPAI Mirror, with its strong strength and rich experience, has become an outstanding representative in the field of LED Mirror. With 23 years of manufacturing experience in the industry, we are one of the largest LED Mirror manufacturers, suppliers and factories in China.

Our LED Mirror production base covers an area of 100,000 square meters and is a model of technology and efficiency. This huge innovation workshop accommodates more than 100 sets of automated production equipment and more than 800 passionate employees, providing a solid guarantee for the manufacture of each product. And has more than 60 R&D team members. Their professional knowledge and innovative ability provide infinite possibilities for the development and design of each DAPAI Mirror product.

We are proud of our 10 automated production lines, with an annual output of more than 600,000 LED Mirrors, forming the cornerstone of continuous innovation and efficient delivery. Whether it is a customized demand from a customer, or a large-scale production plan, we can provide samples within 3-7 days and complete orders in about 30 days. This excellent delivery speed and reliability provide solid support and guarantee for customers' projects.

In the case of cooperation with world-renowned brands, we provide customers with a one-stop mirror solution, which perfectly combines professionalism and innovation. In a word, DAPAI Mirror is always committed to creating excellent LED Mirror experience for customers with its excellent manufacturing capability, professional team, excellent quality and efficient delivery speed.

DAPAI Mirror Advantages

Operating with precision and efficiency, we employ 10 automated production lines, resulting in an annual output surpassing 600,000 meticulously crafted mirrors.Our specialized production line workshops feature state-of-the-art equipment, including CNC glass cutting machines, engraving machines, and a remarkable 72 units of 24-hour automated injection molding machines.

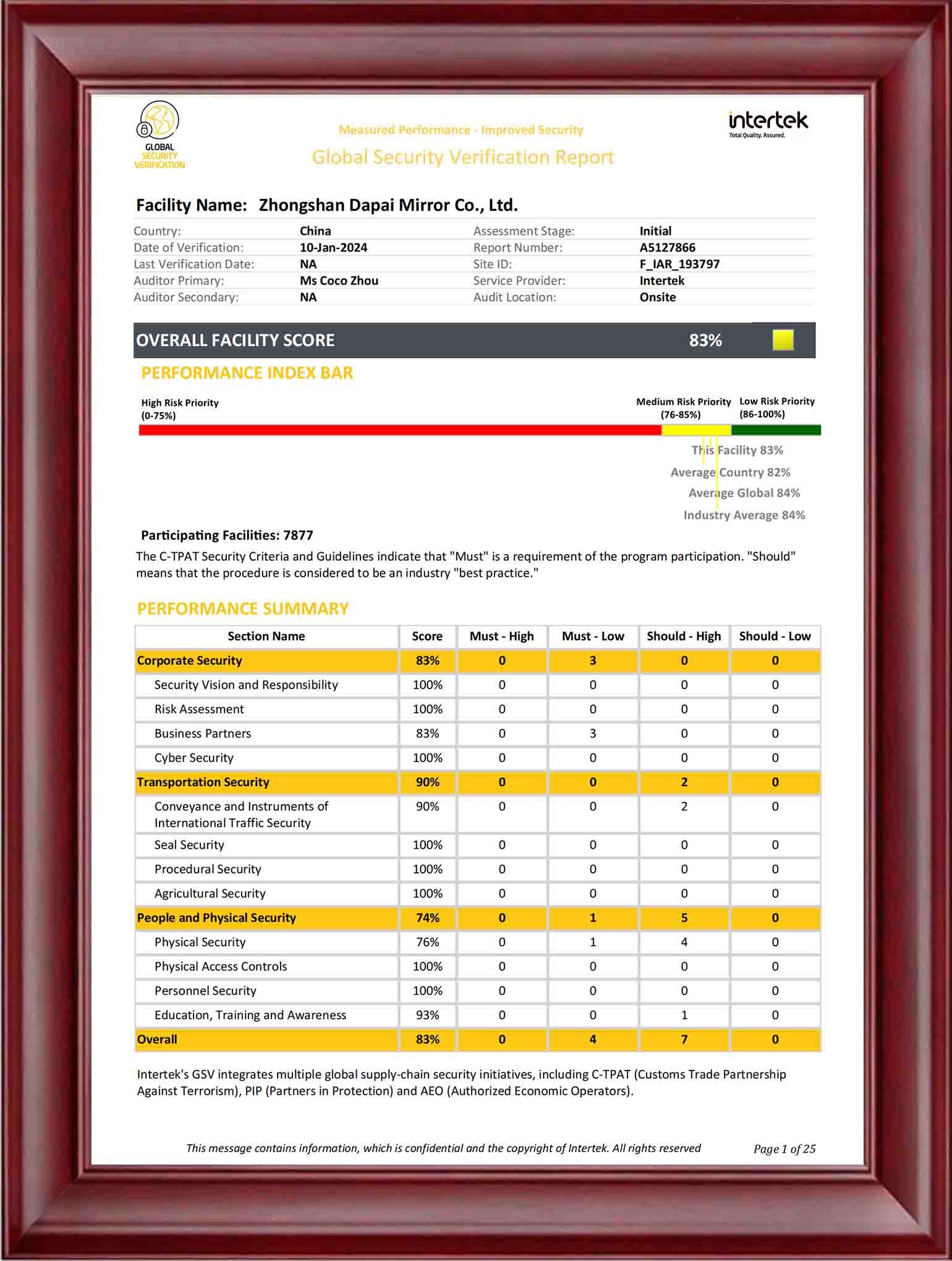

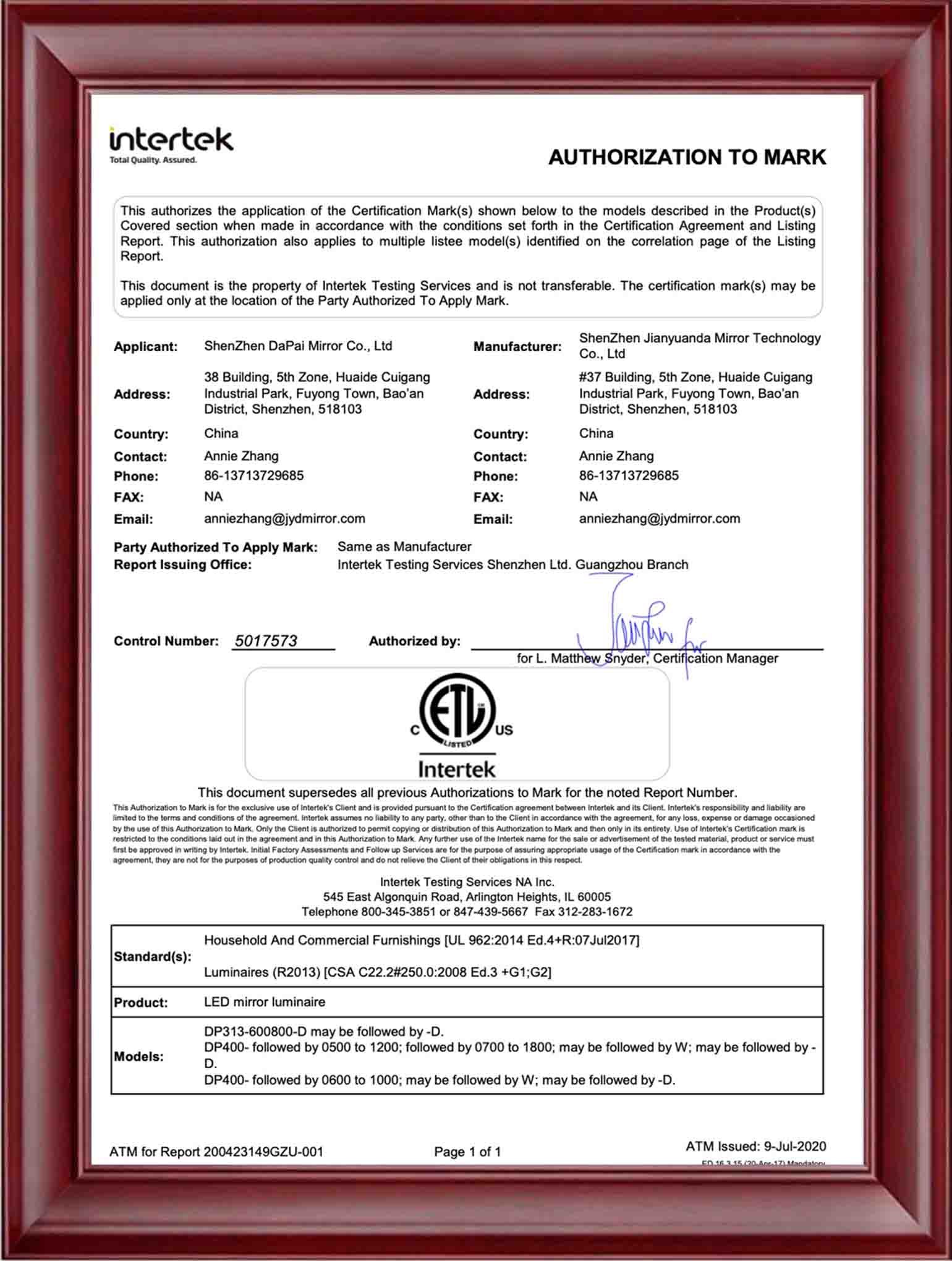

DAPAI Mirror Certification

At DAPAI Mirror, we prioritize excellence in manufacturing and product safety, as evidenced by our comprehensive factory certifications, including BSCI, GSV, ISO14001, and ISO9001. These certifications highlight our dedication to responsible business practices, environmental sustainability, and consistent quality. Furthermore, our LED mirrors have earned international certifications such as UL, FCC, ETL, CE, RoHS, UKCA, and SAA, showcasing our commitment to providing products that adhere to the highest global standards for safety and performance.

BSCI

GSV

ISO14001

UL

ETL

FCC

UKCA

CE

RoHS

DAPAI Mirror Production Workshop

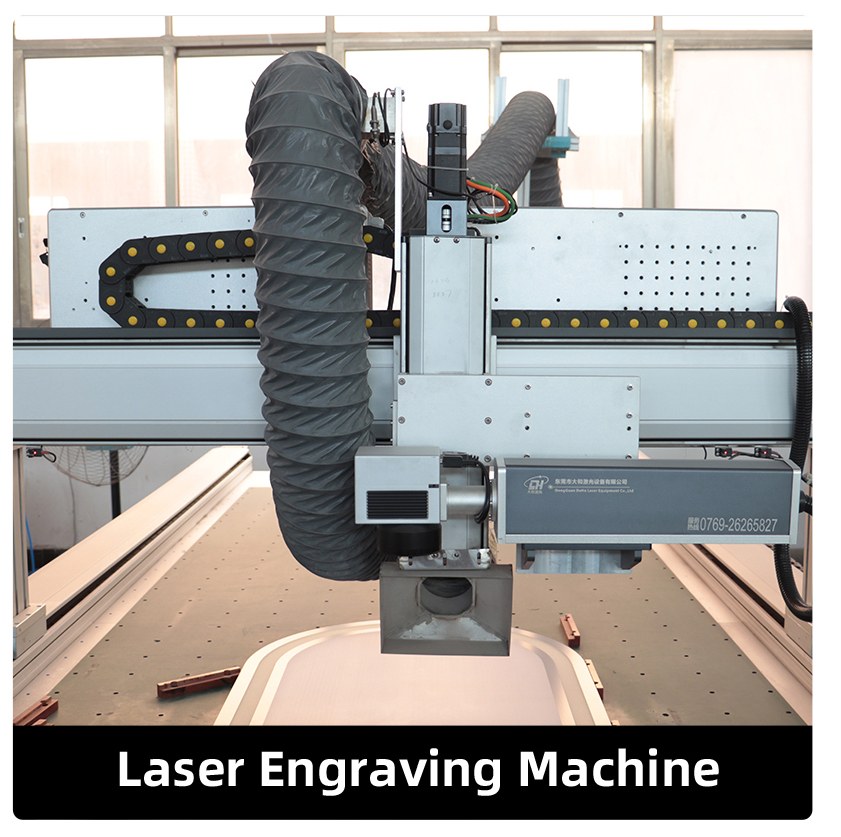

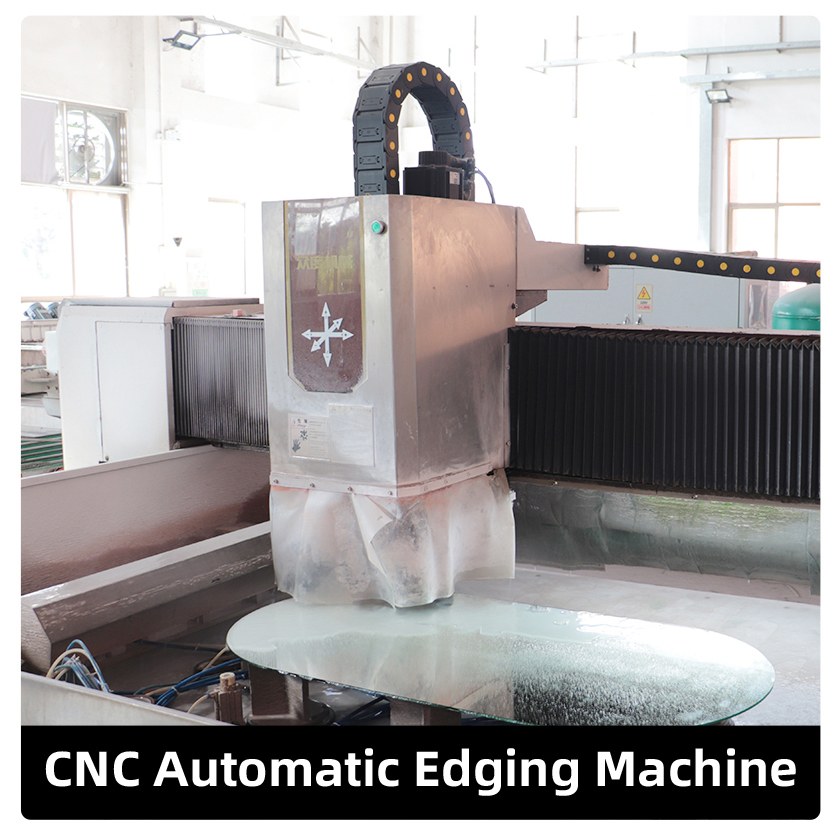

Our professional production line is outfitted with cutting-edge machinery, including Glass Cutting Machines, CNC Automatic Edging Machines, Laser Engraving Machines, Automatic Drilling Machines, Washing and Drying Machines, and Laminating Machines. As a renowned manufacturer, supplier, and factory specializing in wholesale LED mirrors, we ensure each product meets our stringent standards for excellence and innovation.

DAPAI Mirror Injection Molding Workshop

DAPAI Mirror's injection molding workshop is a cornerstone of our manufacturing capabilities, housing 72 state-of-the-art automatic injection molding machines that operate around the clock. This advanced facility enables us to produce high-quality mirror components with precision and efficiency. Our injection molding process is meticulously monitored to ensure consistency and adherence to strict quality standards. By utilizing these machines, we can quickly respond to large-scale orders and maintain a steady supply of top-tier products to our clients.

Glass Cutting Machine

The Glass Cutting Machine allows for precise cuts and shapes, ensuring that each mirror produced meets our stringent standards for excellence and design, making it an essential tool in our manufacturing process.

Laser Engraving Machine

Laser Engraving Machine is a state-of-the-art tool that allows us to add intricate and personalized designs to our mirrors. This precise technology ensures that every engraving is clear and detailed, enhancing the aesthetic appeal of our products.

CNC Automatic Edging

The CNC Automatic Edging Machine at DAPAI Mirror represents our commitment to technological advancement and precision. It provides automated, accurate edging, ensuring that every mirror has a polished and refined look, contributing to the high-quality craftsmanship that defines our brand.

Automatic Drilling Machine

Automatic Drilling Machine allowing us to create precise holes in our mirrors with speed and accuracy. This machine ensures that each mirror is perfectly crafted to meet our high standards of quality and functionality.

Laminating Machine

The Laminating Machine at DAPAI Mirror is essential for producing high-quality mirrors with added longevity. It seamlessly bonds protective layers to the glass, ensuring that each mirror is not only beautiful but also built to last, reflecting our dedication to safety and excellence.

Washing And Drying Machine

The Washing and Drying Machine is key to maintaining the pristine condition of our mirrors. It uses advanced technology to remove dust and residues, followed by rapid drying to prevent water spots, ensuring that every mirror reflects our commitment to excellence.

DAPAI Mirror Workshop

DAPAI Mirror's production workshop is a hub of excellence, boasting over 800 skilled professionals dedicated to crafting high-quality mirrors. Our facility includes specialized production areas for makeup mirrors and larger mirrors such as bathroom mirrors, mirror cabinets, Hollywood bulb mirrors, and full-length mirrors. With 10 automated production lines and 72 24-hour automatic injection molding machines, we ensure efficiency, precision, and consistency in every product we create.

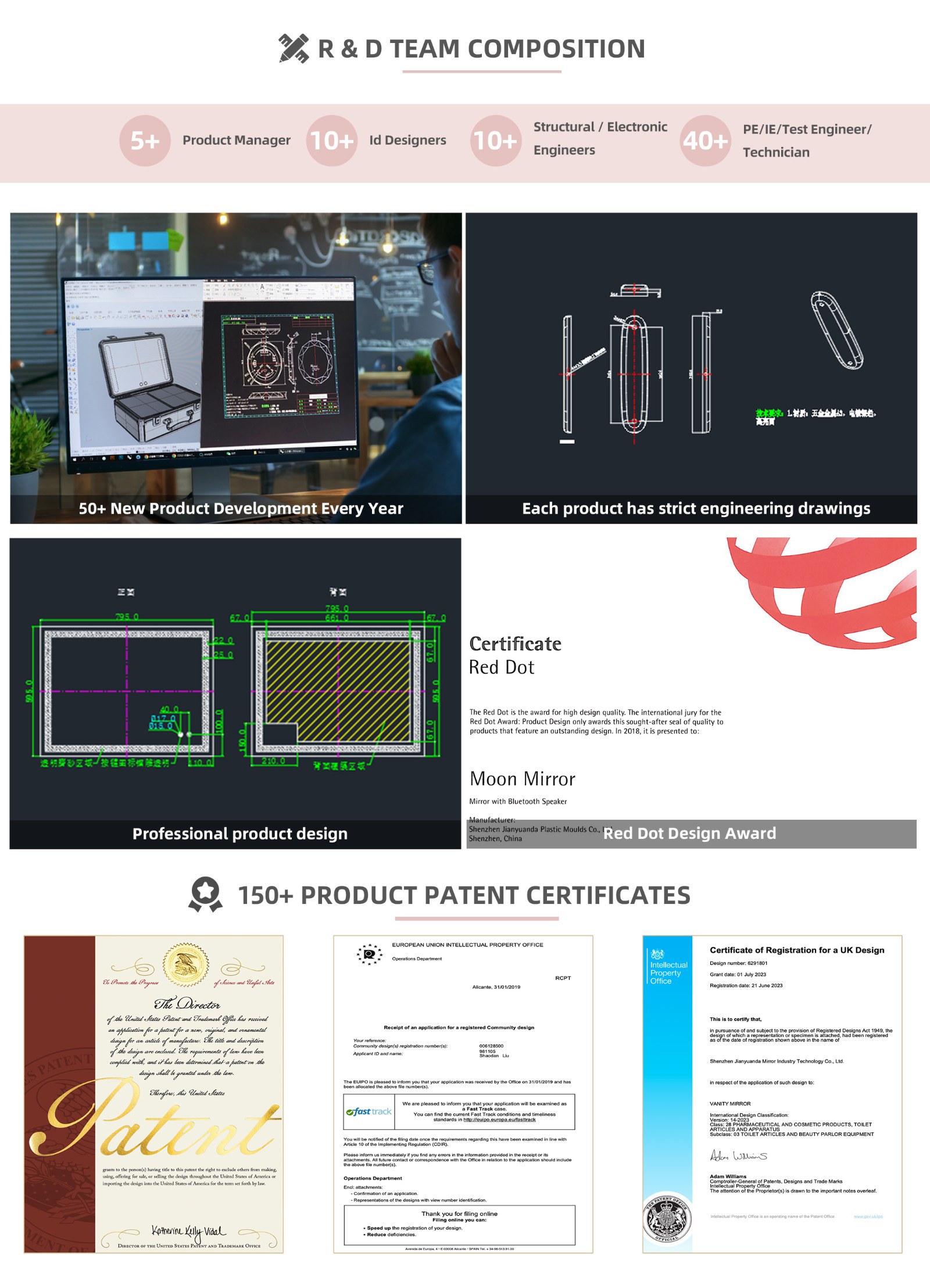

DAPAI Mirror's Award-Winning R&D Team

DAPAI Mirror's R&D Team is a powerhouse of innovation and creativity, driving the development of cutting-edge beauty solutions. Our team comprises over 5 skilled Product Managers, 10+ talented ID Designers, and 10+ dedicated Structural and Electronic Engineers, all working in harmony to push the boundaries of design and technology.

With the support of 40+ experienced PE/IE/Test Engineers and Technicians, we take pride in our ability to introduce over 50 new products annually, each meticulously crafted to meet the highest standards of quality and performance. Our products are not just visually appealing but are backed by strict engineering drawings and professional product design, ensuring functionality and durability.

Our commitment to excellence is recognized by the prestigious Red Dot Design Award, a testament to our team's relentless pursuit of perfection.

With 150+ product patent certificates, the R&D center has been deeply involved in the design and R&D of LED mirrors for many years, and has accumulated rich market experience and technical R&D capabilities. It is in a leading position in the industry, and its tri-fold mirror products have become the largest-selling products in the European and American markets. One of the LED mirror products.

OEM&ODM One Stop Solution

Our dedicated team specializes in providing customized solutions tailored to meet the unique needs and specifications of our clients. Whether you're looking for a specific design, size, or functionality in your mirrors, DAPAI Support is equipped to deliver high-quality, innovative products that reflect your brand's vision.

Our OEM & ODM services encompass a wide range of mirror types, including LED makeup mirrors, vanity mirror and more. We take pride in our ability to bring your ideas to life, from concept development to final production. Our one-stop solution ensures a seamless process, with expert guidance at every step, including design consultation, prototyping, manufacturing, quality control, and logistics.

With DAPAI Support, you can expect exceptional craftsmanship, cutting-edge technology, and a commitment to customer satisfaction. Partner with us for your OEM & ODM mirror needs, and experience the convenience and excellence of our one-stop solution services.

English

English  Spanish

Spanish  Polish

Polish  German

German  Arabic

Arabic  French

French  Russian

Russian